森茂 |

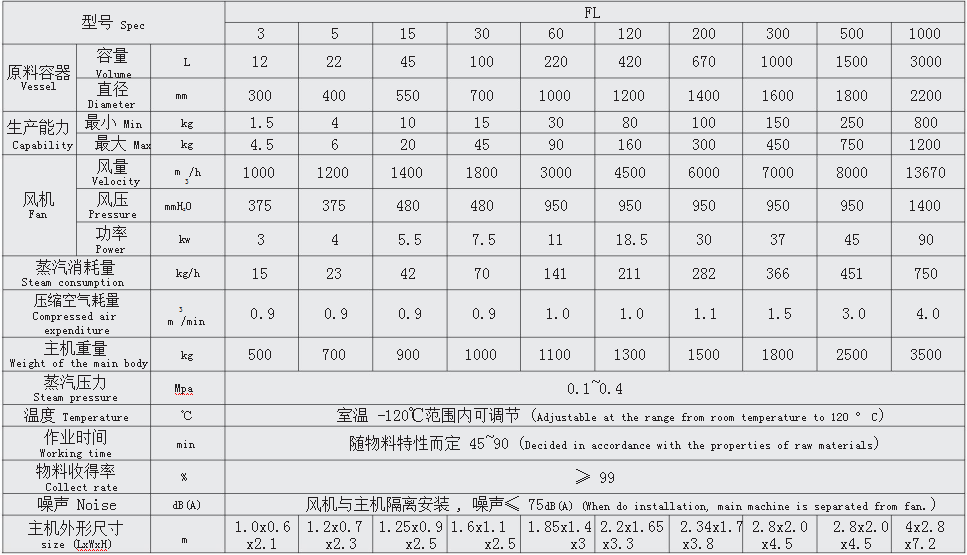

参考报价:电议 型号:FL

产地: 在线咨询

|

FL 系列沸腾制粒干燥机

FL Series Fluidized Granulator

物料粉末粒子,在原料容器(流化床)中呈环形流化状态,受到经过净化后的加热空气预热和混合,将粘合剂溶液雾化喷入,使若干粒子聚集成含有粘合剂的团粒,由于热空气对物料的不断干燥,使团粒中水分蒸发,粘合剂凝固,此过程不断重复进行,形成理想的、均匀的多微孔球状颗粒。

◆

The powder granule in vessel (fluid bed) appears in the state of fluidization.

It is preheated and mixed with clean and heated air. At the same time the

solution of adhesive is sprayed into the container. It makes the particles

become granulating that contains adhesive. Being of unceasing dry through

hot air, the moisture in the granulating is evaporated. The process is carried out

continuously. Finally it forms ideal, uniform and porous granules.

制药工业中的造粒:片剂颗粒、冲剂颗粒、胶囊剂颗粒。食品工业的造粒:可可、咖啡、奶粉、颗粒果汁、调味品等。

其它行业的造粒:农药、饲料、化肥、颜料、染料化工等。粉状或颗粒状湿物料的干燥。包衣:颗粒、丸剂保护层、着色、缓释、薄膜、肠溶包衣等。

Pharmaceutical industry :tablet capsule, low sugar or no sugar granule of

Chinese traditional medicine.

on.Foodstuff: cocoa, coffee, milk powder, juice of granulate, flavoring and so on.

Other industries: pesticide, feed, chemical fertilizer, pigment, dyestuff and so

Drying: powder or granule state of wet material

Coating: protection layer, color, controlled release, film, or bowels solved

coating of granules and pills.